Carbon Steel Flanges Stands for:-

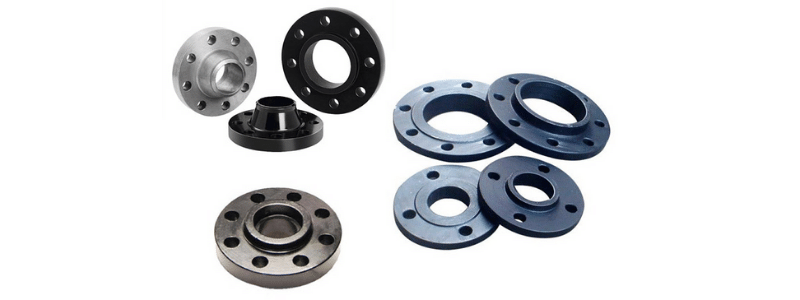

Carbon steel flanges contain carbon, manganese, phosphorus, Sulphur, silicon, copper, nickel, chromium, molybdenum, and vanadium, depending on the material grade. The price list for carbon steel pipe flanges varies depending on the material grade. Flanges of various types and material grades are manufactured by Western Steel Agency.

Carbon steels are available in a wide range of sizes and strengths. The minimum tensile strength and yield strength, respectively, are 485 MPa and 250 MPa. The Flange ANSI B16.5 Class 150 belongs to the medium pressure class of the B16.5 standard flanges. Depending on the nominal bore sizes and wall thicknesses, different pressure classes and materials are used for the flanges.

Carbon Steel Flange Specification, Standard, Sizes List

| Specifications | ASTM A105 / ASME SA105, A105N |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2″ to 48″ |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flanges Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Most Commonly Used Carbon Steel Flange Types

- Slip On Flanges

- Blind Flange

- Weld Neck Flanges

- Socket Weld Flanges

- Threaded Flanges

- Long Weld Neck Flanges

- Lap Joint Flanges

- Companion Flanges

- Orifice Flanges

Different Grades of Carbon Steel Flanges

Carbon Steel Flanges are made of forged carbon steel and are used to join sections of pipe to a pressure vessel, valve, pump, or other piece of equipment. The most common grades available for carbon steel flanges are ASTM A3015, ASTM A182, ASTM A694, and ASTM A105. Carbon steel flanges have a carbon content of up to 2.1 %.

1. Carbon Steel A350 LF2 Flanges:

Carbon Steel A350 LF2 Flanges obtain moderate strength and offer leakage proof connections at a low cost when annealed, normalized, or forged. These flanges are generally more in demand than traditional austenitic stainless steel flanges due to their higher hardness.

2. Carbon Steel A182 Flanges

Carbon Steel A182 Flanges is one of the best chemical experiment and bonding results. These flanges do not wear out quickly. They are widely used in the petroleum, chemical, and paper industries, among others. The characteristics of this flange type make it one of the most dependable products that last a long time and do not need to be repaired soon after installation.

3. Carbon Steel A694 Flanges

Carbon steel A694 flanges meet the high-pressure fluid transmission requirements of oil and gas piping. Manufacturers must design significantly stronger steel to endure both cryogenic and high temperatures as a result of this steel grade’s characteristic. After heat treatment, the steel becomes harder and stronger as the carbon content increases.

Referred Standards:

- B16.5 Dimensional standard for steel pipe flanges and flanges fittings

- B16.34 Valves connect by flanges, threaded and welding end

- B16.47 Large diameter steel flanges

- SP44 Standard for steel pipe line flanges

- API 605 large diameter carbon steel flanges

Coating Types

To prevent carbon steel flanges from rusting or corrosion, a variety of coatings are available:

- Anti-rust painting

- Oil Varnished

- Electric zinc coated (White or yellow zinc)

- Alloy material coated (Lined or Clad)

Carbon Steel Flanges Application

- Carbon Steel Flanges uses in Oil and Gas Pipeline

- Carbon Steel Pipe Flanges uses in Chemical Industry

- Carbon Steel Flanges uses in Plumbing

- Carbon Steel Flange uses in Heating

- ASTM A105 Flanges uses in Water Supply Systems

- Carbon Steel A694 Flanges uses in Power Plant

- Carbon Steel A350 LF2 Flanges uses in Paper & Pulp Industry