- Get Free Quotes

- +91 99209 06048

- +91 22675 21290

- [email protected]

Pipe Fittings, Flanges, Pipes & Tubes

January 15, 2026

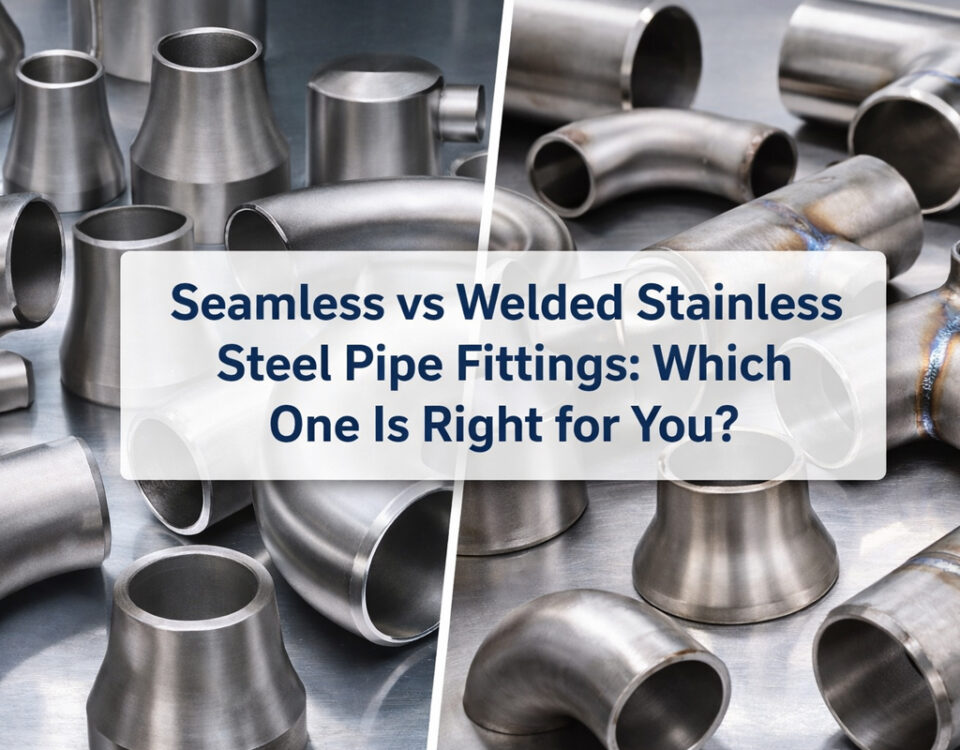

Choosing the right stainless steel pipe fittings is not just about size and grade. One of the most important decisions engineers, contractors, and procurement managers face […]

January 2, 2026

A Practical Guide for Safe and Long-Lasting Piping Systems When selecting stainless steel pipe fittings, one of the most critical but often misunderstood factors is pressure […]

December 18, 2025

A Complete Buyer’s Guide for Indian Industries When it comes to selecting the right pipe fittings for industrial, commercial, or infrastructure projects, one question comes up […]

August 21, 2025

Introduction When building strong pipelines for industries, construction, or residential use, the quality of pipe fittings is crucial. Many materials are available on the market, but […]

August 6, 2025

Introduction When it comes to industrial infrastructure, stainless steel pipe fittings are more than just components; they’re essential for ensuring smooth operations. Whether you’re launching a […]

July 30, 2025

Introduction: Why the Pipe Fitting Industry Is Entering a New Era Take a stroll through any construction site, industrial facility, or urban infrastructure project, and you’ll […]

July 18, 2025

Introduction: The Backbone of Modern Infrastructure In a world where infrastructure and rapid industrialization are key players, stainless steel pipe fittings quietly yet crucially contribute to […]

June 16, 2025

In the food and beverage industry, where hygiene, safety, and quality reign supreme, even the tiniest details can make a huge difference for a brand. One […]

May 19, 2025

Introduction: Built to Withstand the Waves Picture a building holding strong amidst the pounding waves, salt spay, and unrelenting sunshine—day and night, year after year. That’s […]

May 5, 2025

Introduction In the hectic environment of construction, where longevity, efficiency, and safety measure achievement, there’s one such quiet achiever who is making it all happen—stainless steel […]

April 26, 2025

Introduction In a place such as Mumbai, where the atmosphere is humid, coastal, and sometimes hostile to infrastructure, integrity of industrial pipe systems matters the most. […]

March 24, 2025

Stainless steel pipe fittings play a vital role in the chemical and petrochemical industries, ensuring the safe and efficient transportation of fluids, gases, and chemicals. These […]

March 6, 2025

When it comes to the pharmaceutical industry, maintaining a high level of hygiene, safety, and efficiency is non-negotiable. Every component used in the production and distribution […]

February 18, 2025

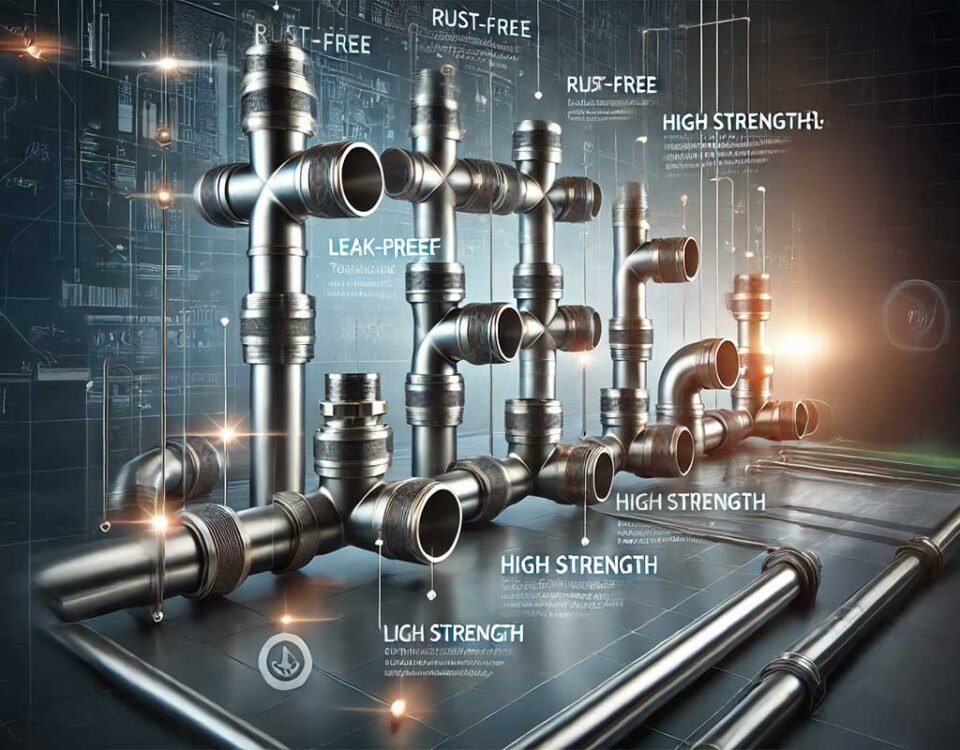

Stainless steel pipe fittings play a crucial role in modern piping systems, ensuring longevity, strength, and resistance to corrosion. Whether in industrial, commercial, or residential applications, […]

February 6, 2025

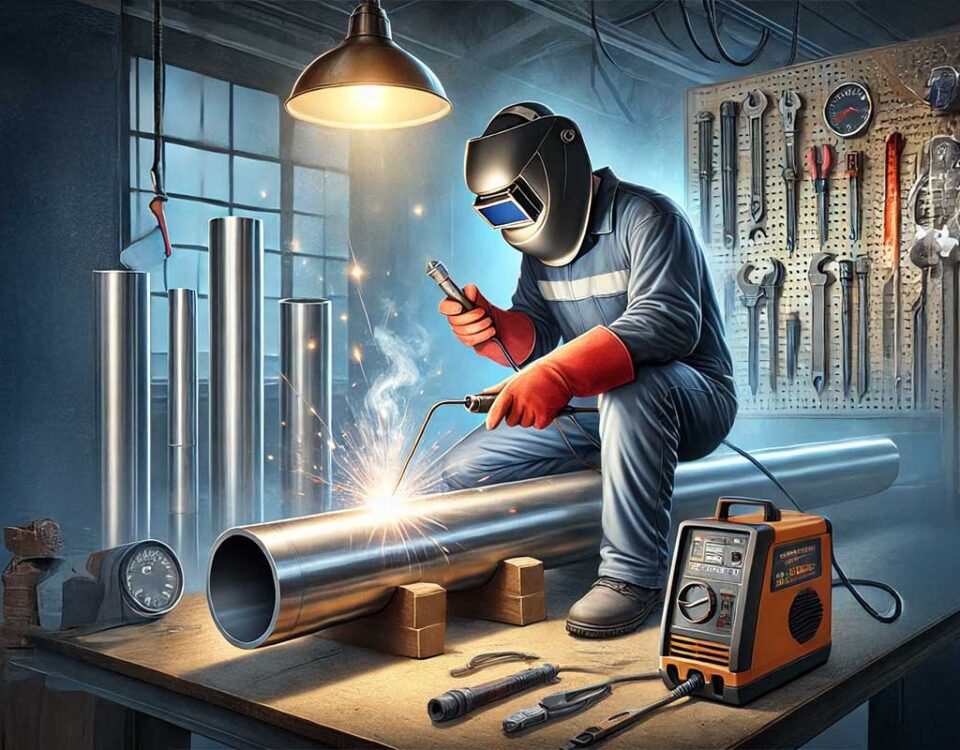

Stainless steel pipes are widely used in industries like construction, automotive, and food processing due to their durability, corrosion resistance, and strength. However, welding stainless steel […]

January 29, 2025

Introduction Imagine walking up a staircase without a railing, crossing a high platform without support, or navigating a slippery walkway without anything to hold onto. It […]

January 8, 2025

When it comes to building or renovating your home, you want materials that can stand the test of time something that offers you peace of mind […]

December 9, 2024

Pipe couplings are essential components in piping systems, connecting pipes to ensure seamless fluid flow and prevent leaks. They come in various types, including compression, threaded, […]

December 2, 2024

Stainless steel pipes often come in two main varieties, 304 and 316. Think they’re the same? Think again. Even though they look alike, each type works […]

November 13, 2024

Stainless steel pipe fittings are considered the most significant plumbing and industrial piping systems elements for connecting, diverting, or controlling fluids. Being highly durable in nature, […]

October 23, 2024

Stainless steel pipe fittings are a crucial part of any project involving fluid handling, piping, or structural requirements, whether it be commercial, industrial, or even residential. […]

October 9, 2024

In the world of plumbing, piping, and industrial systems, one essential component often overlooked is the pipe coupling. These small but critical parts play a […]

September 28, 2024

When it comes to creating a reliable plumbing or piping system, the choice of pipe fittings is crucial. Pipe fittings ensure that pipes are securely joined […]

October 9, 2024

In the world of plumbing, piping, and industrial systems, one essential component often overlooked is the pipe coupling. These small but critical parts play a […]

January 29, 2025

Introduction Imagine walking up a staircase without a railing, crossing a high platform without support, or navigating a slippery walkway without anything to hold onto. It […]

February 6, 2025

Stainless steel pipes are widely used in industries like construction, automotive, and food processing due to their durability, corrosion resistance, and strength. However, welding stainless steel […]

February 18, 2025

Stainless steel pipe fittings play a crucial role in modern piping systems, ensuring longevity, strength, and resistance to corrosion. Whether in industrial, commercial, or residential applications, […]